Production

Information & Operation :

|

Batter Depositor

The depositing head of the Batter Depositor moves at the same speed as the baking moulds

and so deposits the liquid batter centrally in the mould engravings. |

|

|

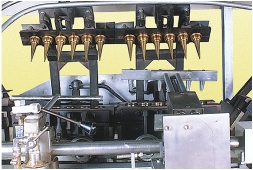

Cone Ejector

The ejector mandrel, synchronized with the speed of the passing moulds, move in to the

loosen the cones from the open baking mould. The cones then drop into the chutes feeding

onto the conveyor of the stacking device. |

|

|

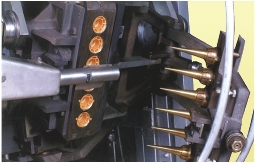

Stripping Device

The cam-operated stripping knife, removes the small lumps of the batter that form on the

outside of the moulds at the steam slots during the baking process. |

|

|

Gas Burners

Our efficiently designed burners ensure uniform heat for even baking

characteristics. It also ensures the optimal gas consumption. |

|

Workers

Required

One skilled and four unskilled workers are required to complete all operations.

Operational Area

Required

The total operational area required is about 1000 to 1500 Sq. ft. (100-150 sq.meter)

Technical Specifications :

| Type |

'Za' 12 |

'Za' 18 |

'Za' 24 |

'Za'30 |

'Za'36 |

| Electrical load in KW* (for LP Gas heated

plant) |

3.2 |

3.2 |

3.2 |

4.0 |

4.0 |

| LP Gas consumption Kg. per hour approx. |

4-8 |

8-12 |

12-15 |

15-18 |

18-21 |

| Electrical load in KW* |

45 |

65 |

87 |

108 |

103 |

| Consumption in KW (Approx.) |

35 |

46 |

62 |

77 |

92 |

Dimensions

(Without automatic stacking device) |

| Length in mm (feet and inches) A |

(10')3580 |

(14')4800 |

(20')6015 |

(24')7205 |

(28')8415 |

| Width in mm (feet and inches) B |

1100 |

1100 |

1100 |

1100 |

1100 |

| Height in mm (feet and inches) C |

1700 |

1700 |

1700 |

1700 |

1700 |

| Net Weight in Kg. |

3000 |

4000 |

5000 |

6000 |

7000 |

| Weight including seaworthy packing |

4250 |

5250 |

6500 |

7500 |

8500 |

| Shipping space approx. in Cubic feet/m3 |

(380)11 |

(650)18 |

(900)25 |

(1300)36 |

(1700)47 |

|