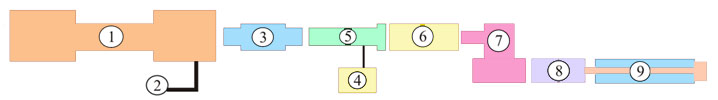

TYPICAL WAFER PLANT LAYOUT

1. Wafer

Oven 4. Planetary Cream

Mixer. 7.

Wafer Cutting Process.

2. Batter

Mixer. 5. Cream Spreading Process. 8. Wafer

Fanning Device.

3. Sheet removal & stress

reliever. 6. Book

Cooler. 9. Packing

Process.

FEATURES : FRAMELESS DESIGN / LOW FUEL CONSUMPTION

The machine features a sturdy and torsion resistant steel

frame work. Non-corrosive protection is afforded to the heat

losses, and heat transfers between inner and outer casings are

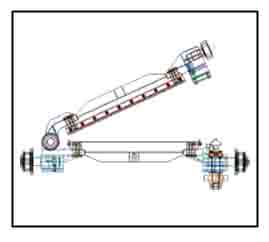

reduced to be absolute minimum. The tong chain evolved is

extremely strong and almost maintenance free.

|

OPERATION :

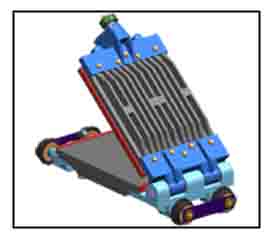

When the batter gets deposited, the upper and lower baking plates

are pressed together and locked. The high closing pressure is absorbed by large

size closing rollers located above and below the tongs. Locking is effected by means

of hook, and bearing clearance which has no effect on the closing mechanism or on

the thickness of the wafer sheet. Batter depositing system ensures uniform sheet weights and waste free and optimum

batter usage. |

Batter Deposit |

Sheet Cooling |

Sheet Removal |

HEATING:

Burner

|

High Efficiency triangular burners can be adjusted for an extremely even application of heat over the entire surface of the baking plates. |

|

INSULATION:

Hinged Doors

|

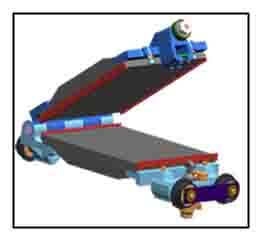

Fully opened hinged doors along the entire length on both the sides of

the baking machine permit total access to the interior for ease of cleaning and

maintenance.

|

CONTROL PANEL:

|

Control cabinet containing all units for the Automatic

Baking Machine and incorporate the following functions:

Safety switches with over load and over voltage relays,

fault-current circuit breaker. Optional temperature

measurement by sensor can be

provided. |

|

TECHNICAL DATA:

Size of the Baking Plates 470 x 350 mm

| Type |

WA 48 |

WA 60 |

WA 72 |

| Output of wafer

sheets/hour(Back Cyled=2m) |

1440 |

1800 |

2160 |

| Cream filler Wafers/hour |

200-225 Kgs |

250-275 Kgs |

300-325 Kgs |

Gas

Heating:

L.P.Gas consumption Kgs/hr (approx)

Electric load in Kw |

30-35

9kw |

38-42

9kw |

44-48

9kw |

Dimensions in mm.

Length

Width

Height

Weight in Kg. (approx.) |

10,000

1350

2450

9000 |

12,000

1350

2450

11250 |

14,000

1350

2450

13500 |

| Shipping space in cubic

metres (approx.) |

32 |

40 |

46 |

* Modifications Reserved

Aditional Link

|

|

|