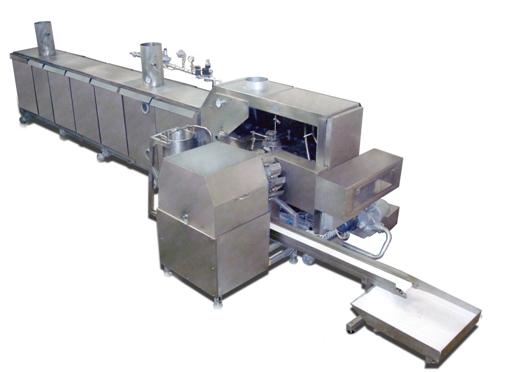

Automatic Rolled Sugar Cone Machine

(RS-Series) :-

|

Rolled Sugar Cone Machine (RS - Series)

R&D Engineers supply automatic machines for Rolled Sugar Cones. The ‘Rs-Series’ of machines are designed with latest technical standards for an econmical results.

These machines are clearly laid out and easily accessible. The bearings and lubricants used are of long life and the links between the baking plate are also maintenance free.

Procedure

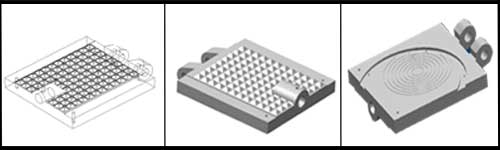

The prepared batter mix is put into a holding tank. A measured volume of batter mix is pumped through dosing pipes, which deposit it onto each of the baking plates, these plates move continuously through the oven. The lower baking plates have a grid-patterned surface that imprints its pattern on the outside of the cones. The hinged top baking plates have a limiting ring for giving a thick ring on the top of the cone.

As the top plates close down onto the bottom ones, the limiting ring enters the groove to form a barrier as the batter mix spreads over the plate- this boundary forms the top rim of the cones. The lower plates are heated from underneath by a gas burner. As the baking plates return on the underside, a lower gas strip burner heats the other baking plate. |

Batter Dosing

|

Wafer thickness is determined by the distance between the closed baking plates, and is fixed

during machine manufacturing. Batter dosing determines the final wafer size and shape. The

deposit is normally directed into the centre of the baking plate, but then has to be adjusted for

the

wafer length. |

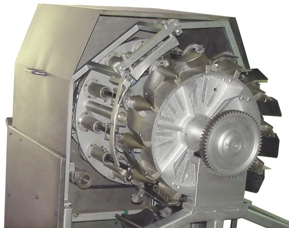

Rolling Device

|

The wafer is taken off the lower plate and handed over to the horizontally formatted rolling

device. The rolling which results from this principle is the requirement for a

wafer with a distinct squared pattern and an even thickness of the wafer which allows

a slow

and careful turning of the rolling core. |

Conveyor

Baked cup and cone is transferred to a conveyor & ready for packing.

Control Panel

Control panel allows an easy observation and the open access of all important

areas of the machine.

| No.of

Baking Plates(Tongs) |

Size of Plate

(apprx)

<mm’mm> |

Type of heating

[all types of gas;propane, butane,natural gas] |

Number

of tongs/

multiple

usage |

Gas

consumption

per hour

(apprx) |

Electrical

load in

KW |

Production

capacity

<pcs/h> |

Possible

products |

| 120 Sec Cycle Time* |

| RS

24 |

250*250 |

all

types of gas |

24 |

5 - 7 |

5 |

700-.750 |

rolled sugar

cones, waffle

cones, waffle

bowls, waffle

sheets. |

| RS

36 |

250*250 |

all

types of gas |

36 |

7-10 |

5 |

1080-1100 |

| RS

48 |

250*250 |

all

types of gas |

48 |

10-14 |

5 |

1440-1500 |

| RS

60 |

250*250 |

all

types of gas |

60 |

15-18 |

5 |

1800-1900 |

Photo Feature

Control Panel |

Batter Tank |

Batter Deposition |

Burners |

Sheet take off |

Preparing Cone |

|

|