Gaufrier automatique

ZW

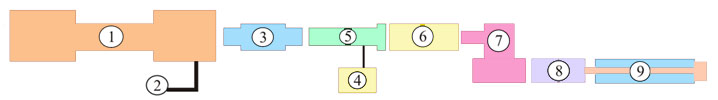

Process Chart

| Wafer Oven |

Batter Mixer |

Cream Mixer |

| Cream Spreading M/C. |

Wafer Cutting M/C |

Packing Machine |

| Take Off Device |

Process

Details

Adding Batter to Holding tank

|

Feeding Batter to plates

|

Sheet Removal |

Technical specifications

| ZW Automatic Wafer

Baking Machine |

ZW 12 |

ZW 18 |

ZW 24 |

ZW 30 |

ZW 36 |

| Output of wafer sheets/Hr. |

360 |

640 |

860 |

1070 |

1280 |

GAS HEATING:

LP Gas Consumption/Hr |

4 |

6 |

8 |

10 |

12 |

| Electric Load (kw) |

3.5 |

3.5 |

3.5 |

3.5 |

3.5 |

Electric Heating :

Connected load in KW |

27 |

40 |

51 |

63 |

75 |

| Current Consumption in KW/Hr |

20 |

32 |

40 |

50 |

60 |

| Dimensions (approx.) |

| Length |

2500 |

3300 |

4100 |

5200 |

6300 |

| Width |

1100 |

1100 |

1100 |

1100 |

1100 |

| Height |

1500 |

1500 |

1500 |

1500 |

1500 |

| Net Weight |

1300 |

1900 |

2500 |

3250 |

4050 |

| Weight incl. Seaworthy packing |

1800 |

2500 |

3250 |

4100 |

5000 |

| Shipping space in m3 |

4.5 |

5.5 |

7.0 |

9.0 |

11.0 |

| Cream filled wafer/Hour *

(Kgs. approx.) |

18-20 |

36-40 |

48-50 |

60 |

75 |

*NOTE: We are constantly guided by our

principle of offering our customers better and better machines; to give increased

efficiency and higher levels of automation.

The technical data and illustrations are subject to charge without notice.

Output Details

The output is dependent on the following factors

- The sheet weight

- The baking time or cycle

- The cream ratio of wafer and cream

| A |

Wafer Sheet Details |

|

Size |

230X290 |

|

|

Baking Time |

|

Plant Type |

|

|

|

Zw18 |

Zw24 |

Zw30 |

|

|

|

Wafer Sheets

produced/hour |

|

90 Seconds |

|

720 |

960 |

1200 |

|

120 Seconds |

|

540 |

720 |

900 |

|

180 Seconds |

|

360 |

480 |

600 |

|

|

|

|

|

|

| B |

Output Details

(an example) |

Each |

Kgs |

Kgs |

Kgs |

| I |

Baking Cycle taken at 90 sec. |

|

|

|

|

| 1 |

Weight of wafer sheet/hour |

25g |

18 |

24 |

30 |

| 2 |

Wafer: Cream

Ratio |

1:1.5 |

27 |

36 |

45 |

|

Total Production/hour |

|

45 |

60 |

75 |

|

|

|

|

|

|

| II |

Baking Cycle taken at 120 sec. |

|

|

|

|

| 1 |

Weight of wafer sheet/hour |

25g |

13.5 |

18 |

22.5 |

| 2 |

Wafer: Cream

Ratio |

1:1.5 |

20.25 |

27 |

33.75 |

|

Total Production/hour |

|

33.75 |

45 |

56.25 |

*NOTE: We are constantly guided by our

principle of offering our customers better and better machines; to give increased

efficiency and higher levels of automation.

The technical data and illustrations are subject to charge without notice.

Working

Instruction

Automatic Wafer Baking Machine: Type ZW

This machine is equipped with 18/24/30 sets of baking plates, mounted lengthwise in

relation to the direction of throughout. The baking plates are made of a special Grey cast

alloy.

They measure 230mm x 290mm, and are suitable for making flat wafers with pattern depths up

to 3.omm . Deep patterns, logo and ornamental patterns and hollow shape moulds are

available as options.

The machine consists of robust steel frame with a chain path and a continuous link chain

that carries the tong carriages and baking plates. The baking tongs, hinges, locking bolts

and connecting links are robust and maintenance-free, guaranteeing uninterrupted

production and minimizing service time.

We have used low-maintenance, bearings bushes as running wheels and locking rollers. The

tong carriage chain is driven by an infinitely variable gear box with a safety clutch to

prevent over loading.

The baking chamber is attractively cased with doors on both sides and an exhaust hood and

exhaust nozzles for removing baking vapors. Access is easy for maintenance and cleaning.

There is a central control panel at the discharge end of the baking machine that controls

the drive unit,

- The batter pump

- The blower

- Ignition.

The baking time for standard receipts is about 1,5 minutes (12 wafer sheets per minute in

18 plate construction).

The batter pouring system consists of a stainless steel tank, an extremely finely metering

reciprocating pump that is synchronized with the main drive, and a batter pouring. We can

supply either directly pouring or branched batter pourers. The amount of batter is

adjusted by a hand wheel on the reciprocating pump.

Gas Heated Plants:-

This machine is equipped for indirect gas heating all types of gas. It is supplied

complete with all the necessary mixing and control fittings, special burners and a high

pressure air blower.

The ignition and safety system permits completely automatic ignition and monitors the

combustion process. In the event of a pressure loss or a power failure, it automatically

turns the heating off.

Special segmental burners provide a flame pattern that evenly flames all the baking

plates, ensuring ideal heat distribution.

Electrically heated plants:-

The type of machine is equipped with electrical heaters. The heaters are embedded in the

plate itself.

The current is distributed via carbon current collectors through a continuous endless

rail.

|