| دربارة ما | محصولات | خدمات | دستورالعمل ها | داون لود | تماس با ما | پرسش سؤالات احتمالي | نقشه سايت |

| Batter Plants | ماشين آلات قيف بستني | Rolled Cone Machinery | ماشين آلات ويفر | تجهيزات پشتيبان | Belgian Waffle Machine |

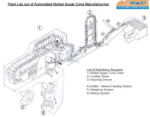

Automatic Rolled Sugar Cone Machine (RS-Series) :-

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| top |